Membrane Plants: reverse osmosis, ultrafiltration, MBR

Expertise, experience and reliability in the membrane plant sector.

- Reverse osmosis plants

- Ultrafiltration plants

- Nanofiltration plants

- Microfiltration plants

- Implanted MBR membrane plants

Demineralization, water recovery and reuse, desalination. Membrane systems for primary, process and exhaust water treatment.

The membrane purification technologies has been remarkably developed in recent years.

Main advantage is that it is not necessary to add additional chemical agents to separate the pollutants from the water.

The principle is very simple because the membranes act as filters and can therefore be used as a valid alternative to traditional plants since energy consumption can be reduced.

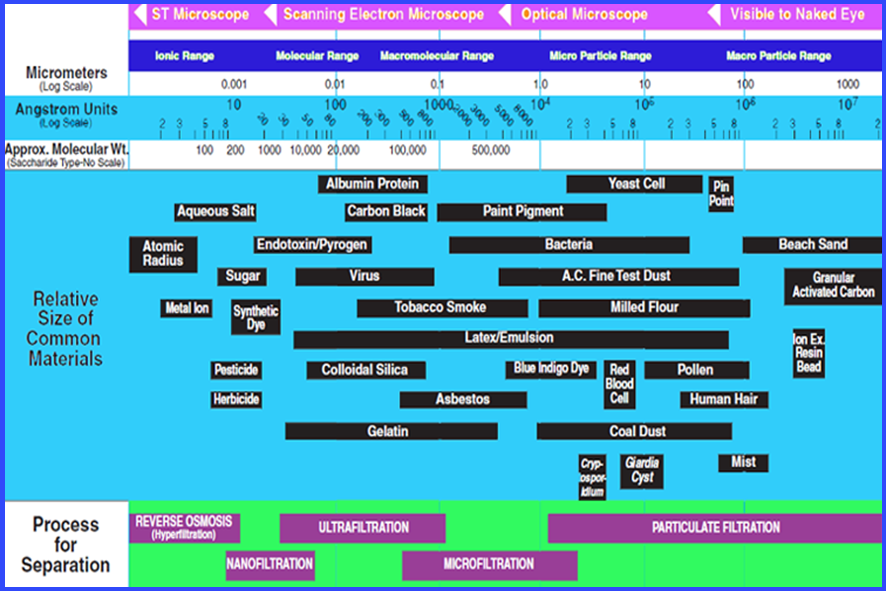

Reverse osmosis, nanofiltration, ultrafiltration, microfiltration and MBR systems use the tangential filtration system..

Membrane plants are mainly used for:

- Demineralization

- Water recovery and reuse

- Total softening

- Partial softening

- Saltwater desalination

- Seawater desalination

- Landfill leachate treatment

- Oil emulsion treatment

- COD reduction

- Degreasing bath treatment and recovery

- Ammonia discharge treatment

- Reduction of nitrogen content

- Penetrant and release liquids treatment

- Potabilization

- Removal of bacterias

- Removal of colored substances

Reverse osmosis and nanofiltration plants

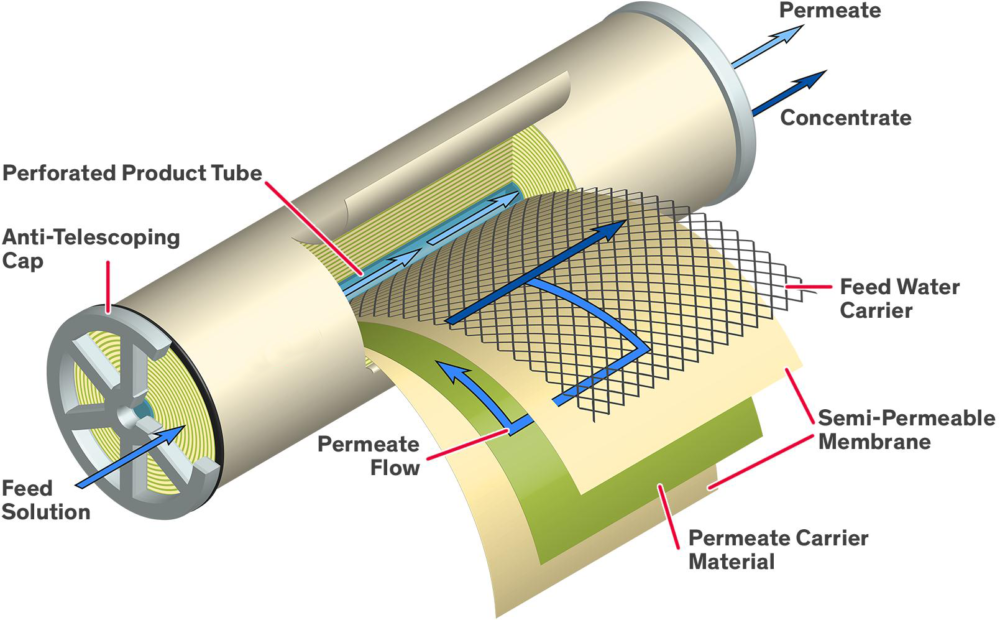

Reverse osmosis plants use the membrane selectivity to obtain the water demineralization. This process doesn’t consist only of a physical obstacle (produced by the membrane pores dimensions) to the passage of the molecules, but it use the different chemical affinity of the solutions with the membrane, permitting the hydrophile molecules (or water-like) passage.

Nanofiltration plants are usually used for softening. Nanofiltration plants differ from reverse osmosis plants for the type of membrane installed. The nanofiltartion membrane has bigger pores and it doesn’t stop all the salts but only the molecules with bigger dimensions. The nanofiltration is mostly use to remove organic solutions (colored substances, nitrates, etc.) and multivalent ions.

Reverse osmosis and nanofiltration plants work at high pressures.

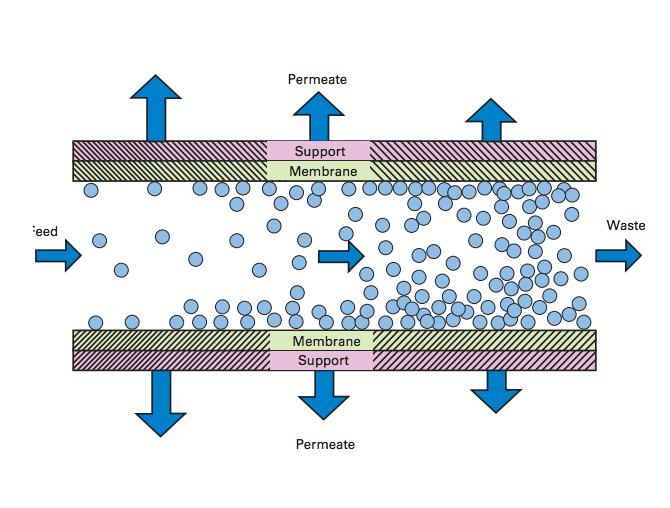

Ultrafiltration and microfiltration plants

Ultrafiltration plants with ceramic membranes are mostly used to divide compounds with medium-high weight molecules. Ultrafiltration plants are applied at the effluent, on close loop, in order to reach the required concentration and a filtrate solution called permeate. The advantage of the ceramic membranes is that they resist to different kind of pollutants and they can be washed with various chemical products and at high temperatures.

Microfiltration plants are mostly used to remove solid particular present in the effluent. Microfiltration plants are often used as pretreatment for reverse osmosis, nanofiltration and ultrafiltration plants. Ultrafiltration and microfiltration plants work at low pressures.

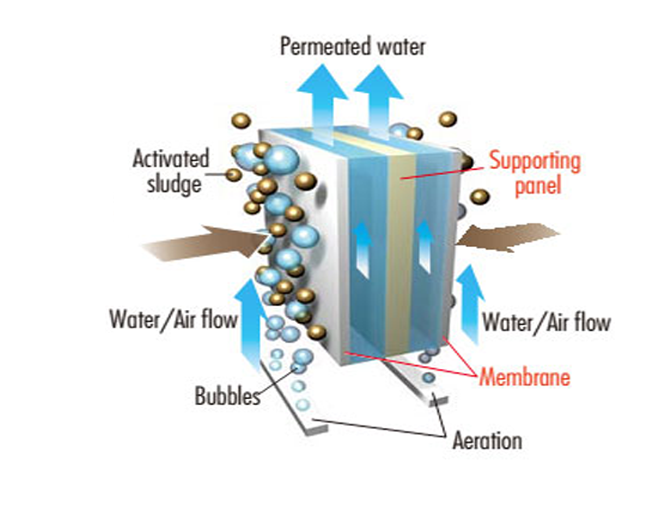

MBR plants (membrane bioreactor)

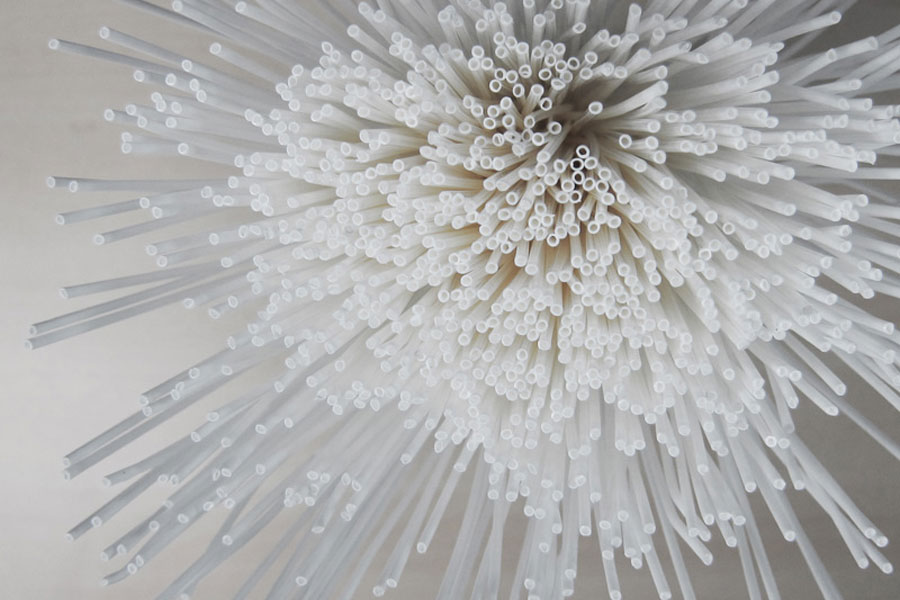

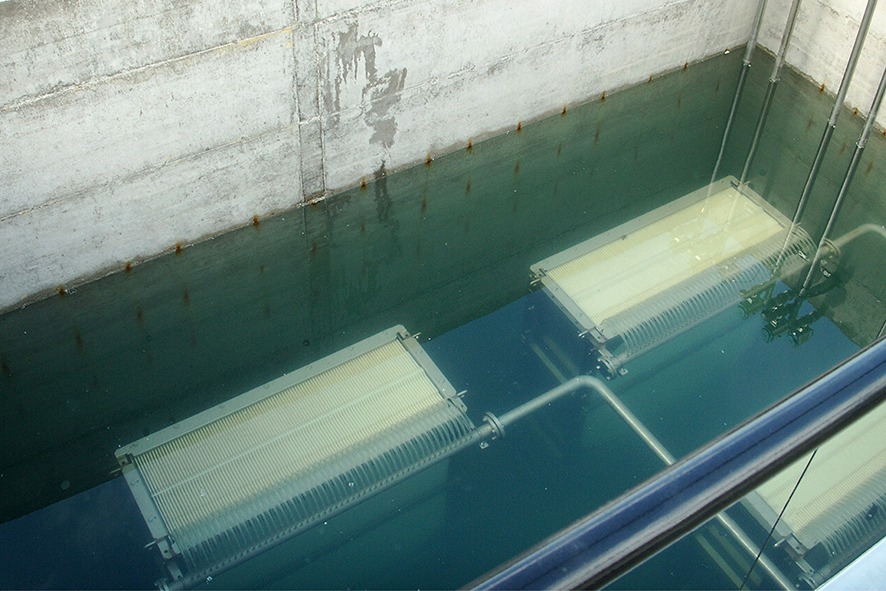

MBR plants use flat sheet membranes. This kind of membranes work submerged in the bioreactor and they efficiently remove suspended solids and pollutants. MBR membranes replaces sedimentation sections.

MBR technology combined with reverse osmosis plants produce an high quality water.

MBR membranes can work submerged in bioreactor containing a lot of activated sludges, helping the BOD and nitrogen reducing process.

MBR membranes combine biological treatment with membrane technology.

MBR technology reduces the dimensions of the biological plant area.